Airflow vortex micro powder machine

Applications: XWDJ turbine mill is mainly applied in the low hardness material comminution, chemical, pharmaceutical, pesticide, dye, paint, metallurgy, ceramics, food, feed, non metallic minerals and scientific research units, as a fine powder and ultra-fine powder processing is the most ideal, the most ef

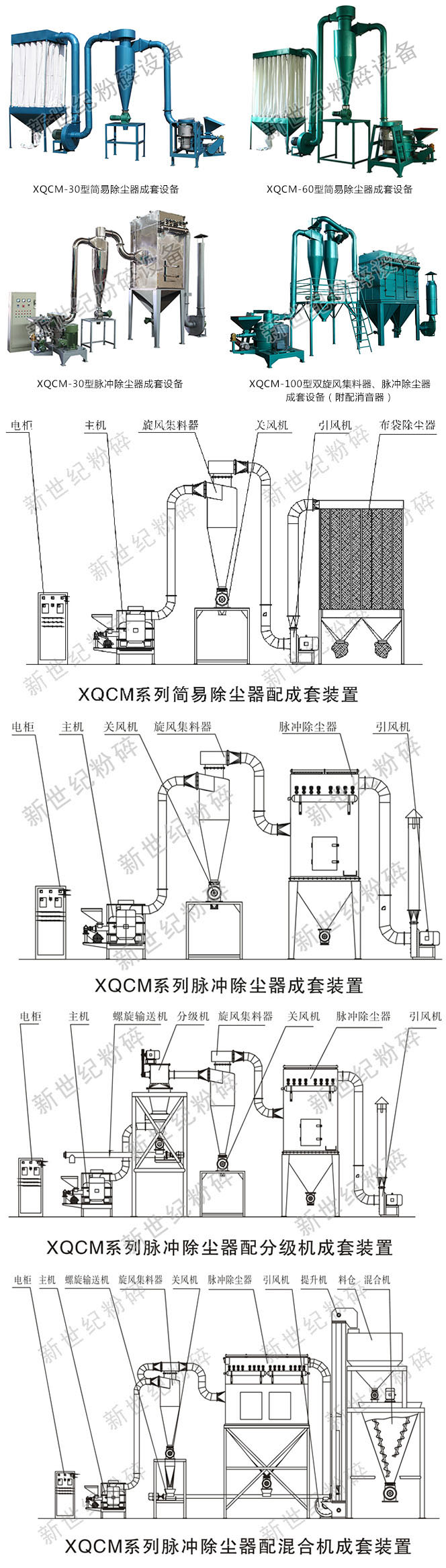

The XQCM series airflow vortex micro powder machine is developed by our company with reference to advanced foreign micro crushing technology and through digestion and absorption. Compared with the pulverizers currently used in China, this machine has leading performance indicators and is suitable for processing various materials. It is capable of handling both thermoplastic and fibrous materials, with uniform product texture and the ability to crush to micro and ultra fine powder levels. It is currently an energy-saving and ideal micro powder production equipment with good performance and high efficiency.

The characteristics of this device are as follows:

1. It is a vertical axis reflection crusher that can simultaneously complete two processing steps of micro powder crushing and micro powder sorting;

2. Equipped with an air flow control valve and a stepless speed regulator with a graded impeller, the fineness of the product can be controlled without stopping the machine. The new bag type pulse back blowing dust collector can collect more than 1um of powder and recover all fine powder without polluting the environment;

3. This machine has an air cooling function and has a low temperature rise during crushing (if there is a special need, a deep water cooling structure can be added). It is particularly suitable for processing thermoplastic and fibrous materials (such as chitosan and other bioengineering materials), basically overcoming the problems of heat sensitive materials being prone to sticking and bioengineering products being damaged by temperature rise, resulting in uniform product particle size and narrow distribution surface.

The crushing fineness of the equipment has reached 1um to 300um. Can be continuously crushed normally, with a production capacity of 500-3000 kilograms per hour.

| 型 号 | XQCM-5 | XQCM-15 | XQCM-20 | XQCM-30 | XQCM-45 | XQCM-60 | XQCM-100 | XQCM-125 | |

| 配套动力(kw) | 粉碎盘 | 4 | 7.5 | 11 | 22 | 30 | 45 | 55-75 | 90-110 |

| 分级叶轮 | 0.75 | 0.75 | 1.1 | 4 | 5.5 | 7.5 | 11 | 15 | |

| 喂料器 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 1.1 | 1.1 | |

| 转速(r/min) | 粉碎盘 | 8300 | 7000 | 5500 | 4000 | 3500 | 3000 | 2000 | 1600 |

| 分级叶轮 | 900-3200 | 800-3000 | 750-3100 | 700-2800 | 650-2600 | 600-2400 | 500-2000 | 400-1600 | |

| 喂料器 | 20-100 | ||||||||

| 风 量 (m3/h) | 250-500 | 700-1200 | 1300-2800 | 2200-3600 | 3600-6500 | 4000-7500 | 8000-12000 | 1200-1600 | |

| 粉碎粒度(um) | 10-300 | ||||||||

| 产 量 (kg/h | 5-150 | 10-200 | 20-600 | 30-1000 | 40-1200 | 50-1500 | 800-3000 | 1200-500 | |

| 重 量 (kg) | 180 | 350 | 600 | 1000 | 1200 | 2000 | 2500 | 3200 | |

粉碎各种物料的性能指标(参考):

| 原 料 | 型号 | 原料粒度 | 成品粒度 | 生产能力(kg/h) |

| 农业化学品 | XQCM-30 | φ5MM | 43um | 450 |

| 大 米 | XQCM-30 | φ2×5mm | 75um | 420 |

| 淀 粉 | XQCM-30 | φ2mm | 28um | 300 |

| 无机矿物 | XQCM-30 | φ5×5mm | 35um | 300 |

| 氧化铁红 | XQCM-30 | φ5mm | 32um | 250 |

| 环氧树脂 | XQCM-30 | ≤10mm | 75um | 200 |

| PVC | XQCM-30 | φ2mm | 100um | 130 |

| 木 屑 | XQCM-30 | φ1mm | 75um | 180 |

| 硅藻土 | XQCM-30 | ≤12mm | 10um | 400 |

| 松 香 | XQCM-30 | ≤12mm | 75um | 650 |

| 砩 石 | XQCM-60 | ≤15mm | 60um | 1200 |

| 氯化钠 | XQCM-60 | ≤15mm | 35um | 1000 |

| 彩 釉 | XQCM-60 | ≤1mm | 27um | 1000 |

| 竹木碳 | XQCM-60 | ≤15mm | 8um | 350 |

| 胶体粉 | XQCM-60 | ≤1mm | 35um | 150 |

| 轻 钙 | XQCM-30 | ≤φ50um | 7um | 300 |

| 活性漂白土 | XQCM-30 | ≤φ80um | 2um | 800 |

| 膨润土 | XQCM-30 | ≤φ80um | 30um | 120 |

| 锻烧高岭土 | XQCM-30 | ≤φ10mm | 25um | 220 |

| 沥 清 | XQCM-30 | ≤φ1mm | 30um | 150 |

| 石 墨 | XQCM-30 | ≤φ80um | 30um | 200 |

| 酚醛树脂 | XQCM-60 | ≤φ1mm | 50um | 600 |

| 莹石粉 | XQCM-60 | ≤φ50um | 8um | 700 |

| 聚四氟乙烯 | XQCM-30 | ≤φ50um | 1um | 100 |

| 硬脂酸 | XQCM-30 | ≤φ2mm | 45um | 200 |

| 氢氧化铝 | XQCM-30 | ≤φ60um | 10um | 200 |

| 白炭黑 | XQCM-30 | ≤φ50um | 6um | 200 |

Tips

XQCM airflow micro grinding is an ideal equipment for ultra-fine grinding of wettable chemical pesticide powders, which can also crush cellulose like materials normally. It has been well applied in many chitosan enterprises and the biotechnology industry, replacing expensive imported equipment.

In response to the current development of the pesticide industry, our company has developed a wettable powder professional equipment with dual functions of crushing and grading. The powder fineness can be adjusted freely without stopping the machine. The unique crushing system and precise turbine grading make the product micro powdery, uniform, with a fineness of up to 325-2000 mesh and automatic cooling function. Suitable for ultra fine grinding in the industries of stearic acid, oxides, and pigments, it is an ideal grinding equipment for wettable powders of chemical pesticides.

In response to the difficulty of crushing chromium oxide green with high viscosity and low melting point in chromium salt plants, XQCM micro powder mill has basically overcome the crushing difficulties of chromium oxide green with high viscosity and difficult discharge through continuous transformation, opening up a convenient channel for the crushing of chromium oxide green.